3D Printing

Turn your ideas into working prototypes or even low-volume part runs with 3d printing

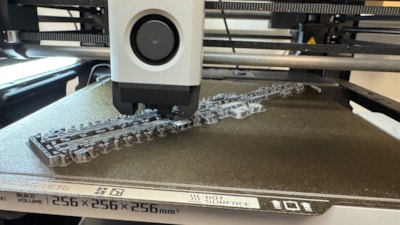

Don’t “think ink” when considering 3D or three-dimensional printing from KKP. It’s completely different than traditional techniques where black or colour pigments are applied to paper or other materials. 3D printing — also termed additive manufacturing —is a process that creates solid, three-dimensional objects.

Working from a digital file, an article is created on a 3D printer that lays down successive layers of material until the object is created. Imagine each of these layers as a thinly sliced horizontal cross-section of the eventual piece. Typically, paper and plastics such as nylon are used in 3D printing services. Other 3D print materials include carbon fibers, epoxy resins, metals, wax, wood filament and more.

As practiced by the pros at KKP, 3D printing services are typically used for two purposes:

- Rapid prototyping: When compared to older prototyping methods (e.g., clay or wood modeling, metal fabricating, etc.), 3D prototypes are remarkably cost- and time-efficient. Long gone are the days of spending thousands of dollars and waiting weeks for a prototype you can hold in your hands. With 3D models, the cost is much lower and the wait considerably shorter. Another plus? Design changes can often be made quickly on the computer and alternate prototypes often 3D reprinted on the same day.

- Rapid manufacturing: 3D printing brings many of the same efficiencies of rapid 3D prototyping to rapid manufacturing. While few would suggest 3D printing services for large production runs, it can be a smart way to manufacture products in short runs or small batches.

Some of the advantages of 3D printing can be explained in that it’s an additive production process. In contrast, subtractive manufacturing involves hollowing out a piece of metal or plastic with a milling machine, for example. That’s often a time-intensive process involving a skilled tradesperson. It’s also wasteful. The material that’s milled away is often scrap. In contrast, 3D printing from KKP applies only as much paper, plastic, metal or resin as needed. Waste is all but eliminated.

Request a Quote